#ecofashion: Indigo Natural Coloring

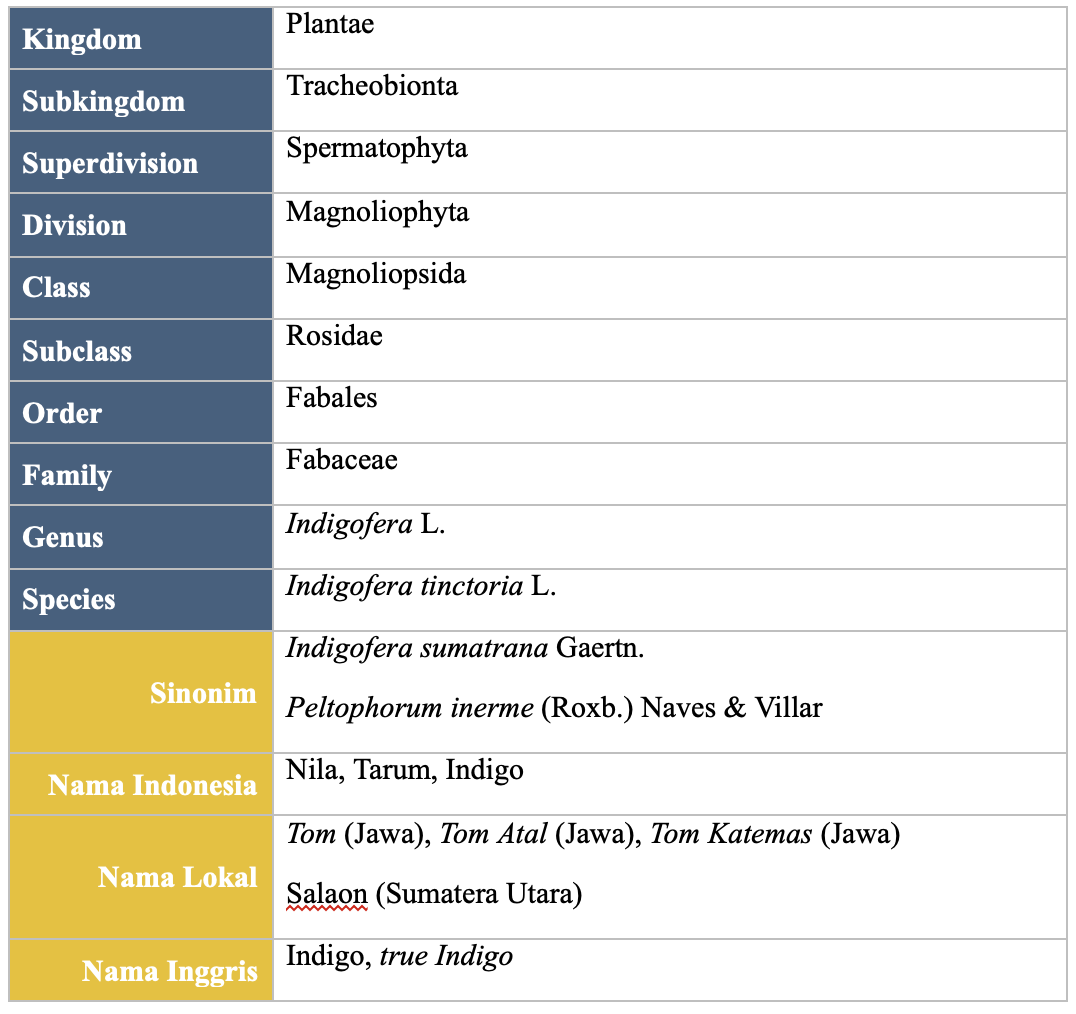

Eco-fashion is a fashion that elevates the concept of ethical sustainable design and environmentally friendly process on its creation and production. Natural textile coloration is a part of eco-fashion creation. A well-known natural dye colorant in Indonesia since a long time ago is indigo blue from indigo plant (Indigofera tinctoria), which produces dark blue color and exists in many parts of Indonesia. In this study, the indigo dye color exploration was created by using three, six and nine times dyeing steps, also using batik treatment as color comparison on cotton fabric and bleaching process as coloring technique variation. The process of eco-fashion fabrication using indigo dye begins by creating dye solution from indigo paste. This process is followed by submerging the cloth into colorant solution then into fixation solution. And so indigo colored fabric will be ready to be processed into an eco-fashion product. The result shows indigo color with different number of dyeing steps and the others with batik treatment are going to produce different kind intensity of blue color. Eco-fashion products which are made from natural dyed textiles will still have their relevance with fashion trends and nowadays society’s fashion taste, especially for those who have special interest in sustainable fashion.

Indigo Blue and Trend

2014 fashion trend from BD+A Design which raises the concept of appreciation for the natural process of renewing life and the use of natural materials as an expression of love and desire to uncover the secrets of nature. One of the trend drivers of this theme is the prevalence of issues and concerns about sustainability in the fashion industry, especially fast fashion, where clothing is mass produced using raw materials that are produced and processed using hazardous chemicals and utilizing labor workers with minimum wages. The industry is considered to have a bad influence on many parties: consumers, producer workers, society, and the environment. Eco-fashion is a fashion with an ethical design concept that is sustainable and environmentally friendly in its creation, production, use and obsolescence processes.

Indigo and Natural Dye

Natural textile coloring is part of eco-fashion creations that still pay attention to the aesthetic needs of clothing in addition to its usefulness and impact on the environment. The use of natural dyes as textile dyes has been a tradition in Indonesia since the people began to recognize the color barrier technique in the process of making traditional traditional fabrics, such as tie-dyed fabrics and batik. The use of natural dyes is closely related to the use of the surrounding environment as a provider of raw materials that can be processed into natural dyes for textiles or other daily products, especially during times when synthetic dyes were not yet found.

Batik cloth (left) and sarong or samping (Aras) of the Baduy Tribe, Banten (right) colored with indigo

Indigo is a natural blue dye derived from the tom or indigo plant. Apart from Java, indigo dye can also be found in several other areas, such as in Sumatra, Sumba and Flores, where in these areas indigo is a distinctive dye for traditional local fabrics. For example, Ulos cloth in North Sumatra and various traditional woven fabrics typical of Baduy (Banten), Sumba (East Nusa Tenggara), Sikka (Flores, East Nusa Tenggara), and other areas.

In general, the color resistance produced from natural dyes is not as strong as the color from synthetic dyes. In this case, natural coloring is difficult to adapt to major industrial standards, also due to other limitations of natural dyes, including the limited availability of dye raw materials, stability and color resistance of fabrics, especially cellulose fibers. For this reason, natural dyes are more suitable when applied to small scale industries. The essence of natural textile dyeing is to utilize raw materials from nature, understand and adapt to its limitations and take advantage of the creative opportunities that exist from these limitations.

The exploration of colors produced by natural dyes, regardless of the type of dye including indigo, is limitless. The color variant in natural dyeing is influenced by many factors, including the type of mordant used, the type of textile material used, the amount of dyeing, and other factors. This exploration of indigo color was carried out based on the variable number of dyeing colors and was applied to cotton cloth, because cotton cloth is a textile material derived from the natural hair of the cotton tree seeds. This research was conducted to explore the potential color variants that can be obtained from natural indigo dyes on cotton fabrics so that they can be applied as eco-fashion creative products.

Natural Coloring Process Using Indigo

Like other natural dyes, indigo requires a mordant additive to aid in the binding of color to textiles and to aid in the direction of the color result. The mordant commonly used together with indigo dye is quicklime or burnt lime (CaO), both for the pre-dyeing mordant process and the final mordant for color fixation.

Apart from being traditionally processed to be designated as custom textiles, fabrics dyed with natural indigo dyes can also be made into textiles that are traditionally processed but are still adapted to current design developments so that the appearance of the fabric will be more contemporary. In creating fabrics for fashion clothes, designers often make various background designs on fabrics so that the fabric has a unique visual appearance, especially if the fabric design is done manually. A variety of background design techniques can also be applied to natural colored fabrics to add aesthetic value, for example batik techniques and fabric bleaching techniques. The addition of a background design technique to the fabric has the potential to change the intensity level of the fabric color.

When compared with other types of natural dyes, tilapia has a different color extraction process, namely by means of fermentation and financing. The fermentation stage is the stage of making indigo paste in which the indigo plant is decomposed with the help of additives in the form of quicklime which is useful for binding indigotins in the plant’s decaying material to form indigo paste. Meanwhile, the process of financing is the process in which the tilapia paste is dissolved in a solution of Javanese sugar water and then left for one day until it becomes an indigo solution that is ready to be used to dye the fabric.

The indigo paste financing process is as follows:

- Weigh 1 kg of tilapia paste;

- Weigh 1 kg of Javanese sugar and quicklime, then dissolved in 8 liters of water;

- Dissolve the weighed tilapia paste into the Javanese sugar solution until it is completely dissolved and homogeneous;

- Let the mixture sit for 24 hours;

- The indigo solution is filtered and ready to use for the dyeing process.

As for the process of dyeing fabrics, namely,

- Mordant the fabric;

- Fabrics are dyed by dyeing them in a natural dye extraction solution;

- The fabric is aerated and then dried in the shade, not exposed to direct sunlight;

- The coloring process is carried out several times dyeing the color, namely three, six, and nine times;

- The fabric is fixed with quicklime mordant solution.

- The fabric is aerated in the shade, should not be exposed to direct sunlight;

- Wash the cloth with clean water and then re-aerate it to dry.

Indigo Blue Color Creation Possibilities

The results of the indigo color coloring process with the number of dyeing variables indicated that there were differences in color intensity between three, six, and nine times dyeing. The more dyeing is done, the darker the color intensity will be. Experiments of dyeing variation with natural indigo dye showed a difference in color intensity in the final result, although not too significant. These color variations allow fashion designers to be creative with simple variations in natural fabric dyeing methods so that unique fabric color variants are obtained for use in eco-fashion products. The coloring in the experiments that have been carried out can still be categorized as environmentally friendly because it does not use materials that threaten health and environmental damage.